How a card is made

Perhaps because they are so much a part of our everyday lives, few of us actually pause to consider just what it might take to create 'Britain's Favourite Cards'. And, even if we were to pause, chances are we would still be a long way from realising how much hard work and talent it actually takes. So spare a moment and let us take you on a brief journey. From the very first moments of a card's creation, to when it is picked up from a retail shop's rack.

A Card is Born!

The first idea for a card can come from almost anywhere. At Simon Elvin Ltd the company has a large team of designers and artists, with a separate editorial department taking care of the words.

The Life & Times of a Greeting Card

Well over 1,500 different card designs, each bearing the Simon Elvin Ltd signature, make their way onto the UK market every year. And this becomes all the more impressive when you know what takes place between design conception and delivery to the retailers' racks. So, how is a Simon Elvin Ltd card actually made?

Range Structure

Before any artist puts pencil or paint to paper, the structure of a prospective range is established. In order to balance each range, consideration is given to the format, size and type of board required to achieve the desired effect.

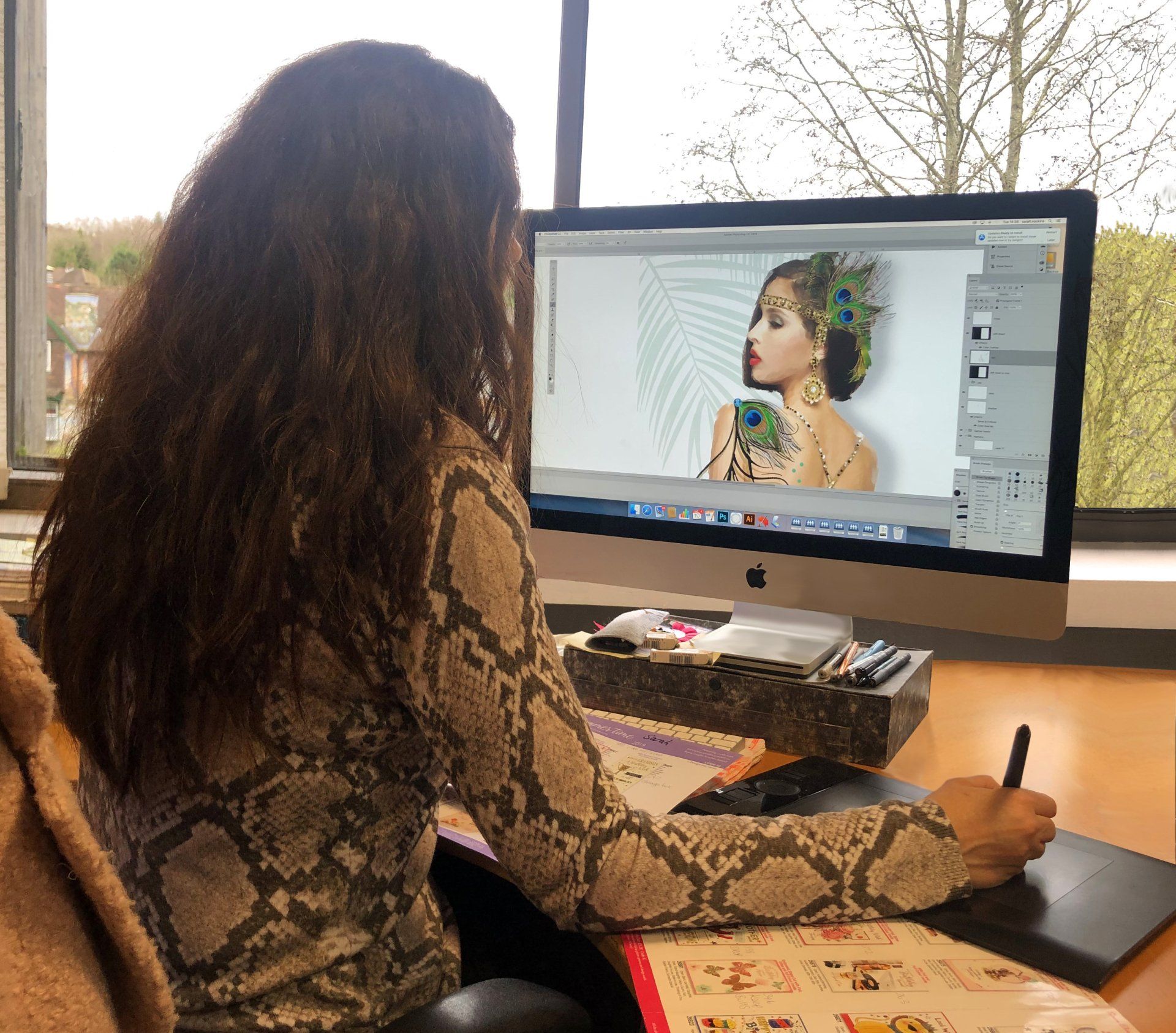

Enter the Artist

With the range structure established, the creative process really begins. A design brief is drawn up and issued to the full time artists who work in the company's studios. Or, on occasions, we may choose to use one of the many budding, or established freelance artists. From a handful of doodled ideas, a suitable design is picked. This doodle is expanded into a more detailed 'thumbnail sketch' (incorporating space for a caption), before the artist embarks on the final piece of artwork. This artwork can be produced using any one of a number of artistic treatments, among which computer illustrations form an increasingly important part alongside the more traditional techniques.

Versing

Creating captions and verses appropriate to each design has always been a Simon Elvin Ltd strength. Under the guidance of the verse Editor, decisions are made about the actual text to be featured and the typestyle in which it is to appear.

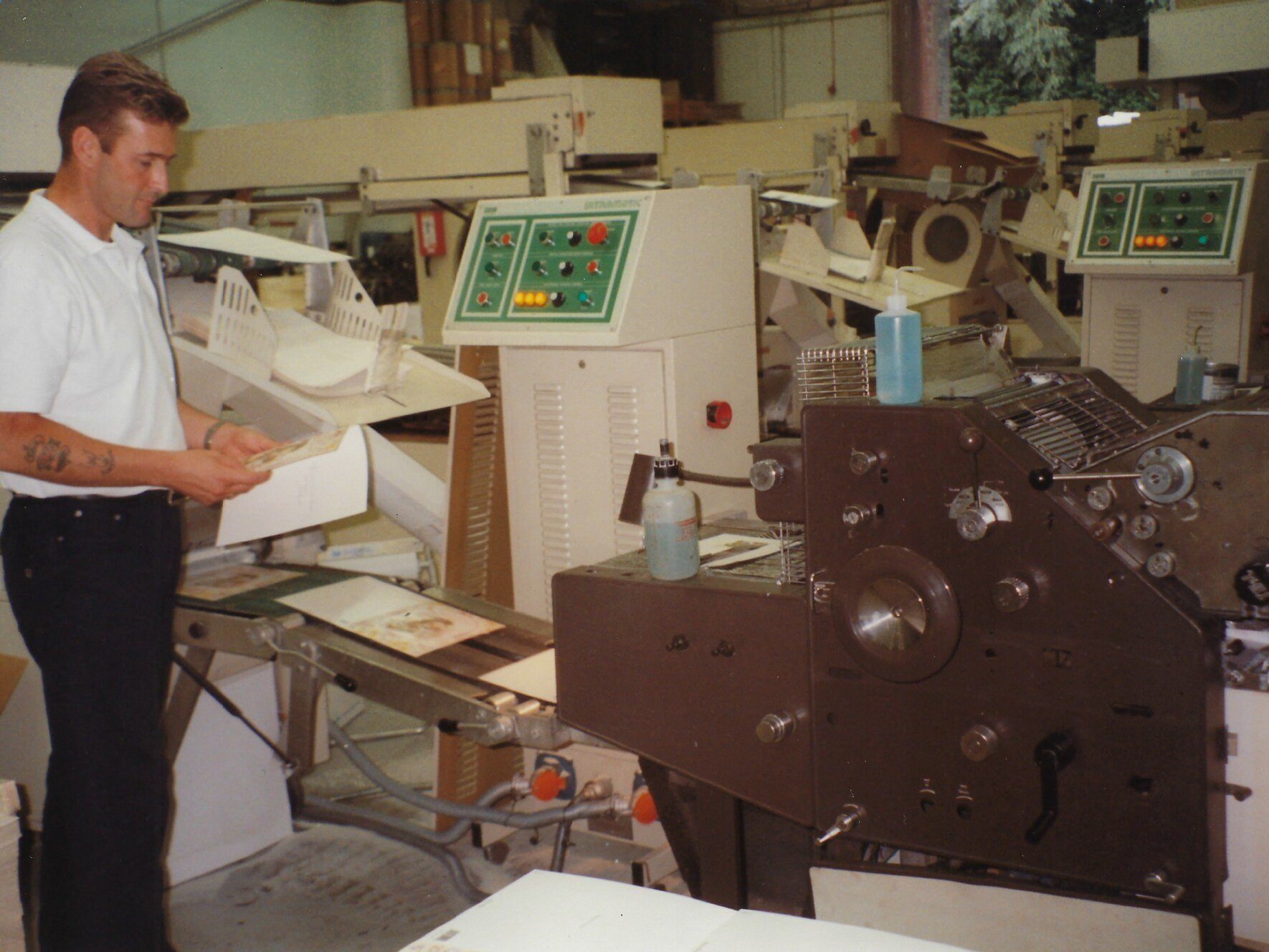

The Reproduction Process

To enable each piece of artwork to be printed, it needs to go through the reproduction stage. This breaks the artwork down into a format the printers can understand and work from. At least 12 cards are normally printed on a sheet, and the computerized repro process produces the large proof sheets showing the appearance of the cards once printed. Each of these sheets undergoes careful scrutiny by the company's production controller, who compares colours on the proofs with the original artwork

The Finishing Touch

Appropriate use of finishes has always been a feature of Simon Elvin Ltd ranges. These complement and enhance the original artwork to provide even better value for money in the finished cards. The most popular of finishes are hot foil, glitter and virko.

Warehousing

Efficient, computerised racking systems, internal lifts and six loading bays enable orders to be turned around very fast indeed. The cards are stored in the 50,000 sq.ft. warehouse, before being dispatched to approved Simon Elvin Ltd distributors.

Retail Stockists

Simon Elvin cards can be found in large numbers in almost every independent retail outlet stocking cards as part of a wider range of offerings, as well as in specialist card shops. The attraction for retailers is the tremendous quality and value for money that, for some 40 years now, have made the Simon Elvin Ltd brand 'Britain's Favourite Cards' for millions of consumers nationwide.

Associated Companies

Copyright Simon Elvin Limited 2021